Step 0: Ideation

I have wanted to hang my bike for a long time to save floor space and to avoid tires deflation and deformation so after learning how to use the CNC machine, the idea came up.

Concept by

DIY Huntress

Step 1: Measurements

1- Measure the handlebar length as it determines the shelf dimensions

2- Mesure the distance between holes in the wall

(I already had holes drilled in my wall for an old purpose and I needed to reuse them. So, this step should be after finishing the part)

Step 2: Sketch on Solidworks

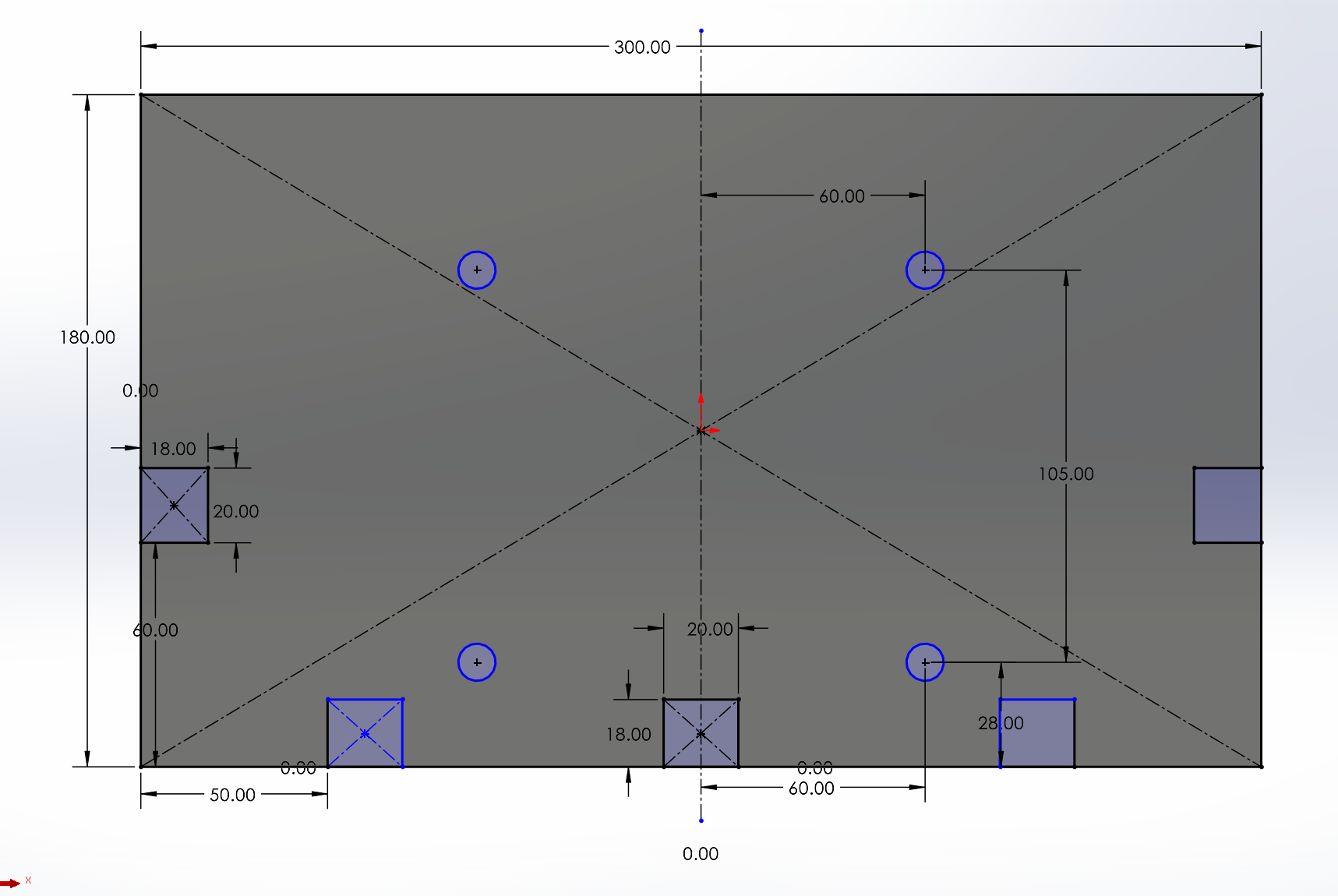

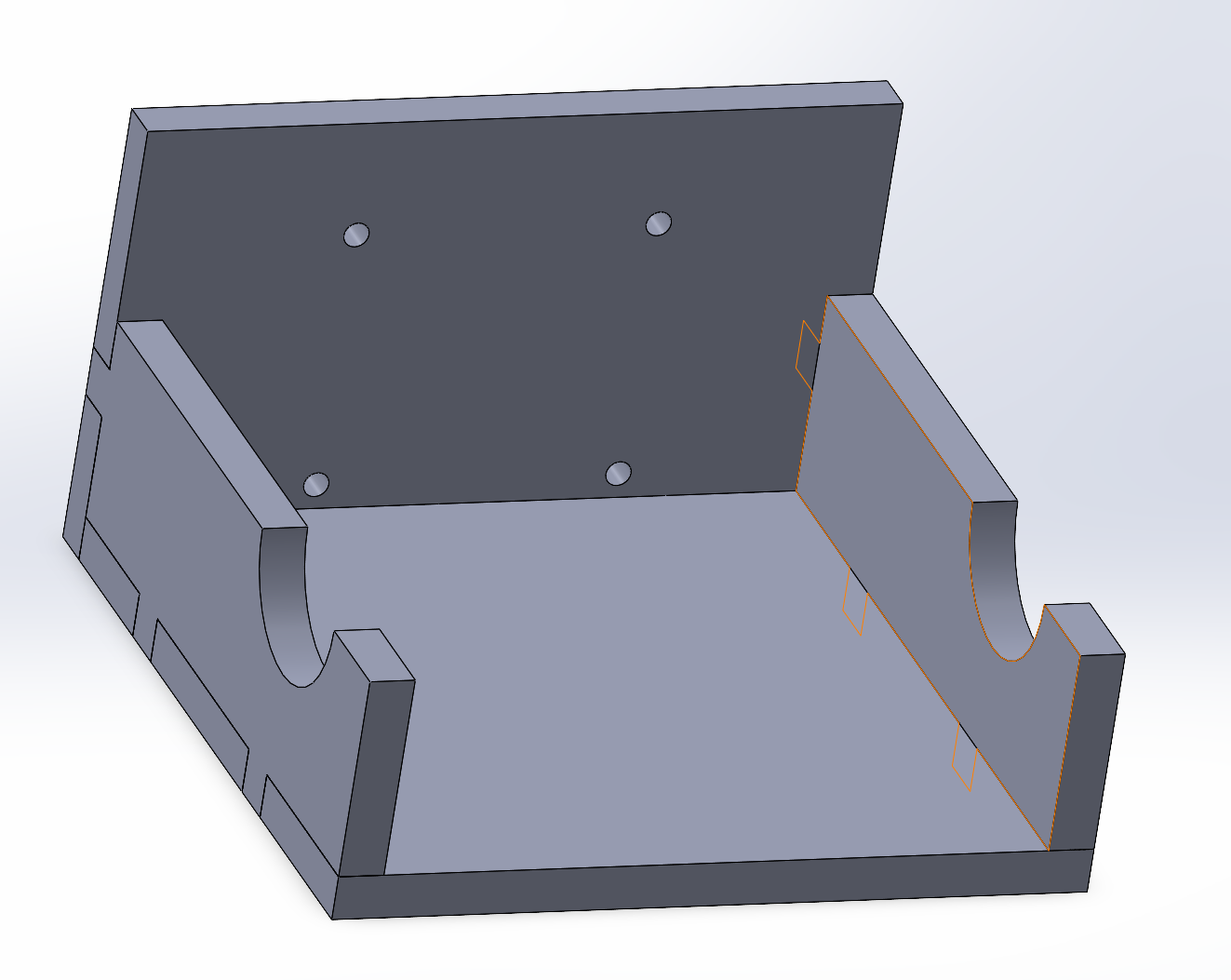

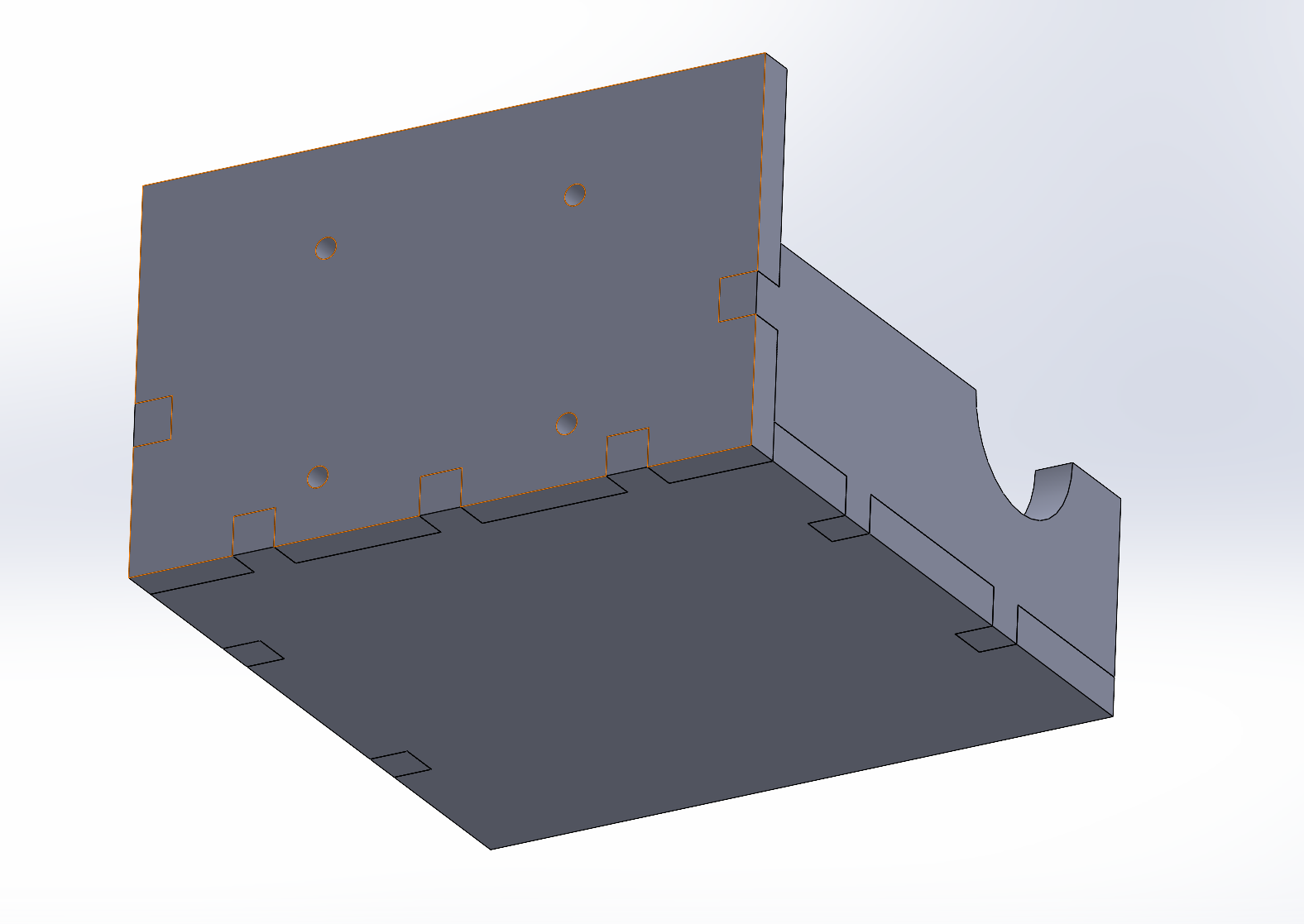

Wall Base:

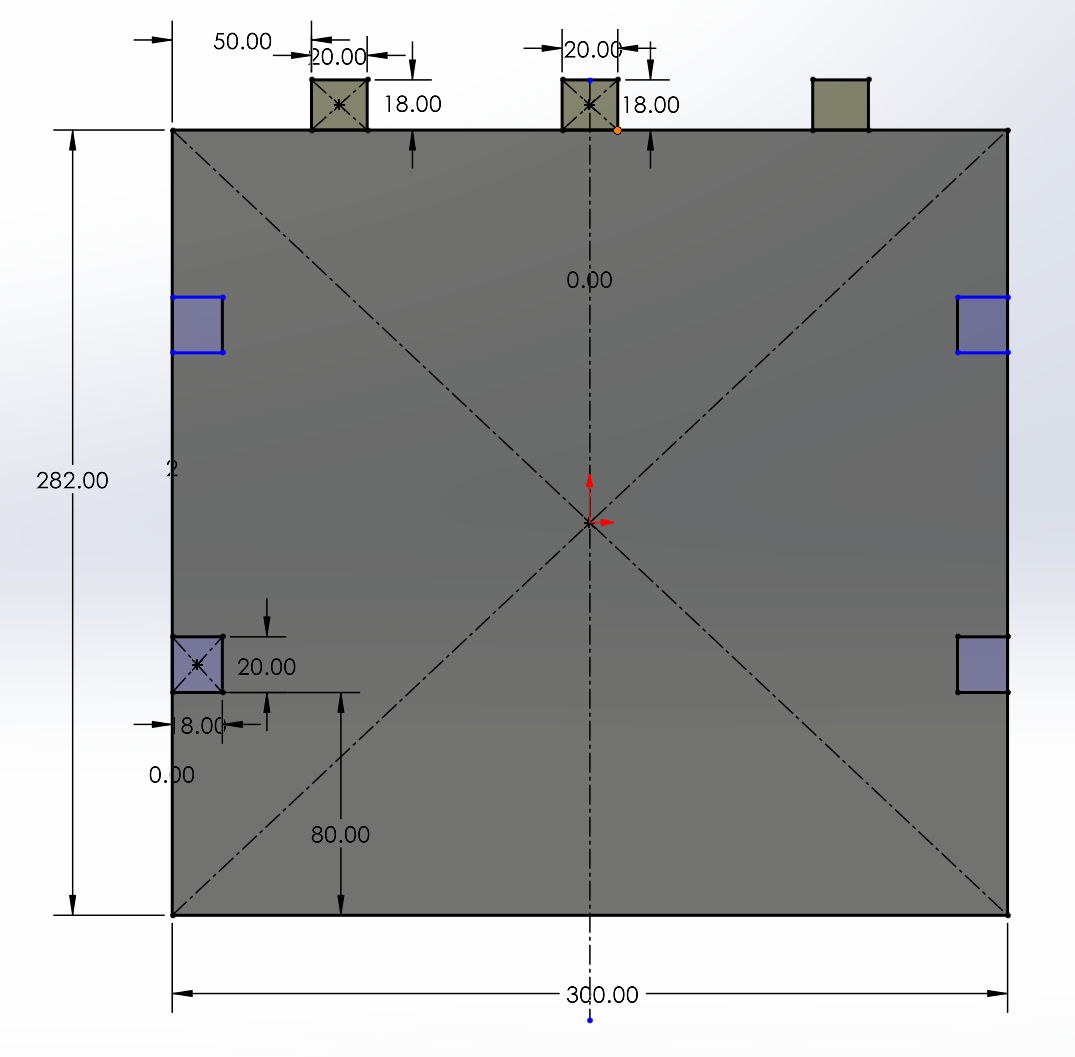

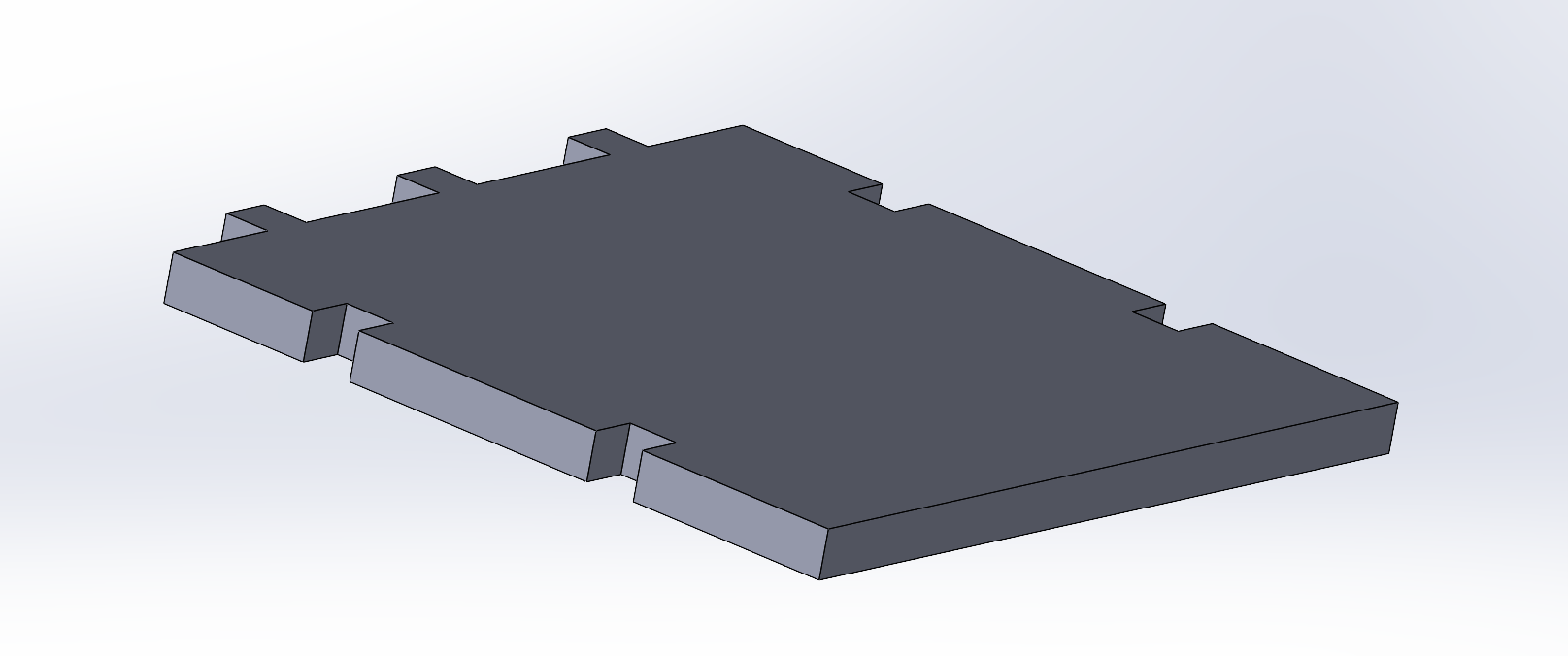

Shelf:

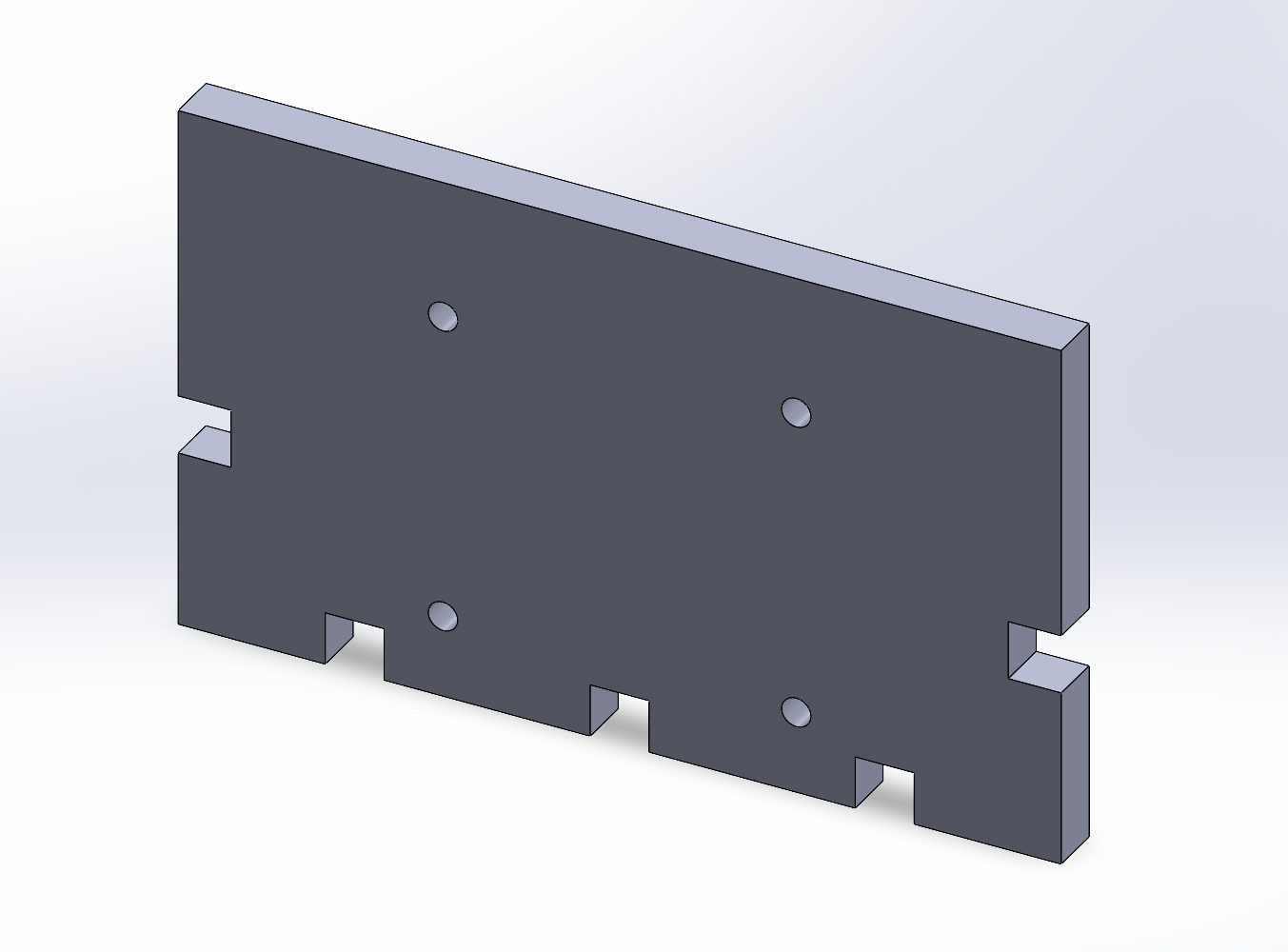

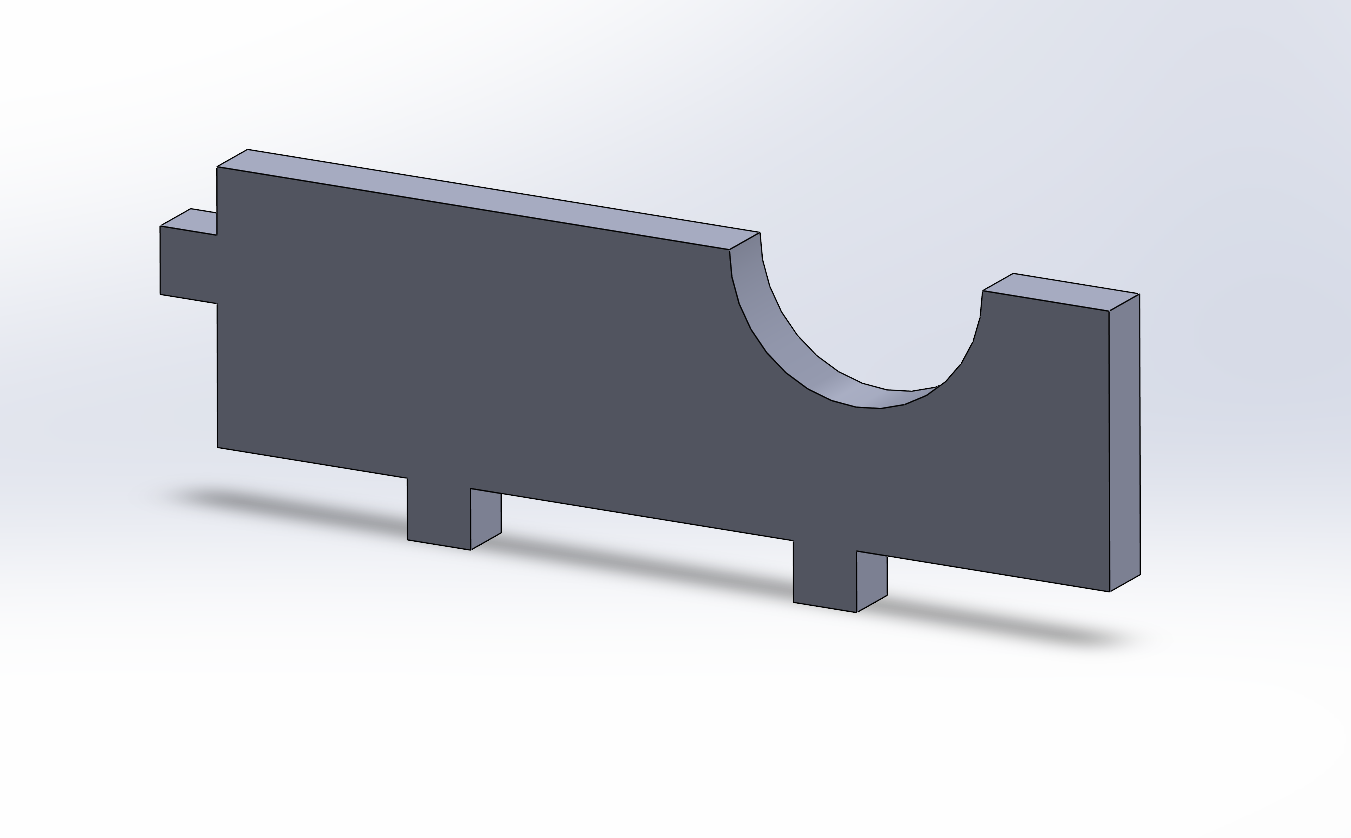

Hanger:

Step 3: Software Assembly

To make sure the parts fit together and it really helps, I had to reassemble about 4 times to make them fit.

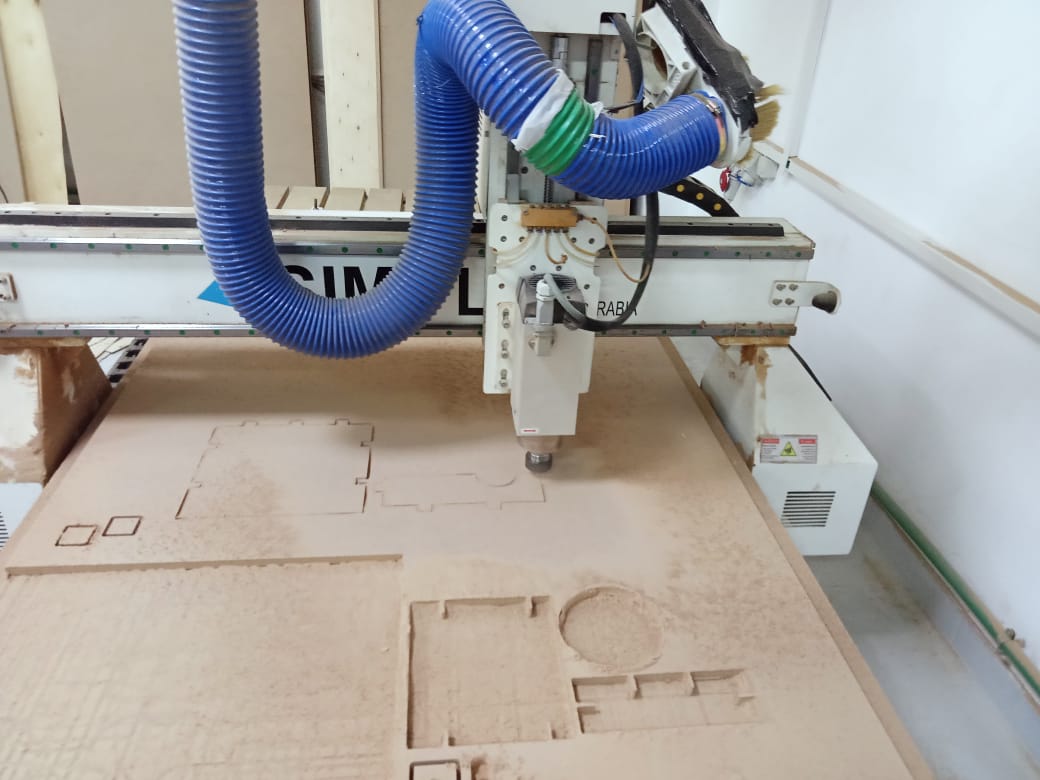

Step 4: Configuration Files

I exported the dxf files from Solidworks and Eng. Ayman helped with Aspire software for the layout cosidering the dog bones.

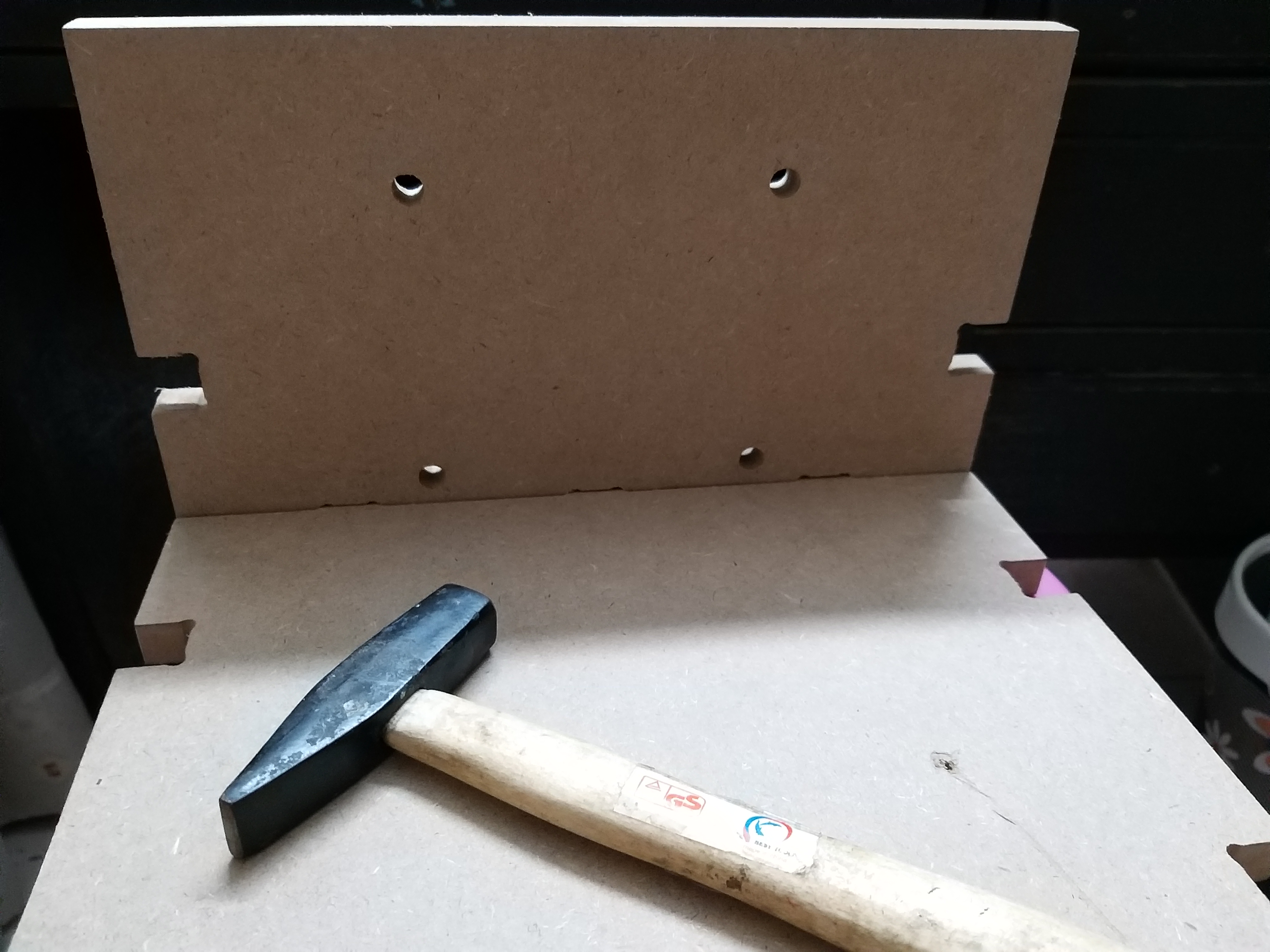

Step 5: Machining

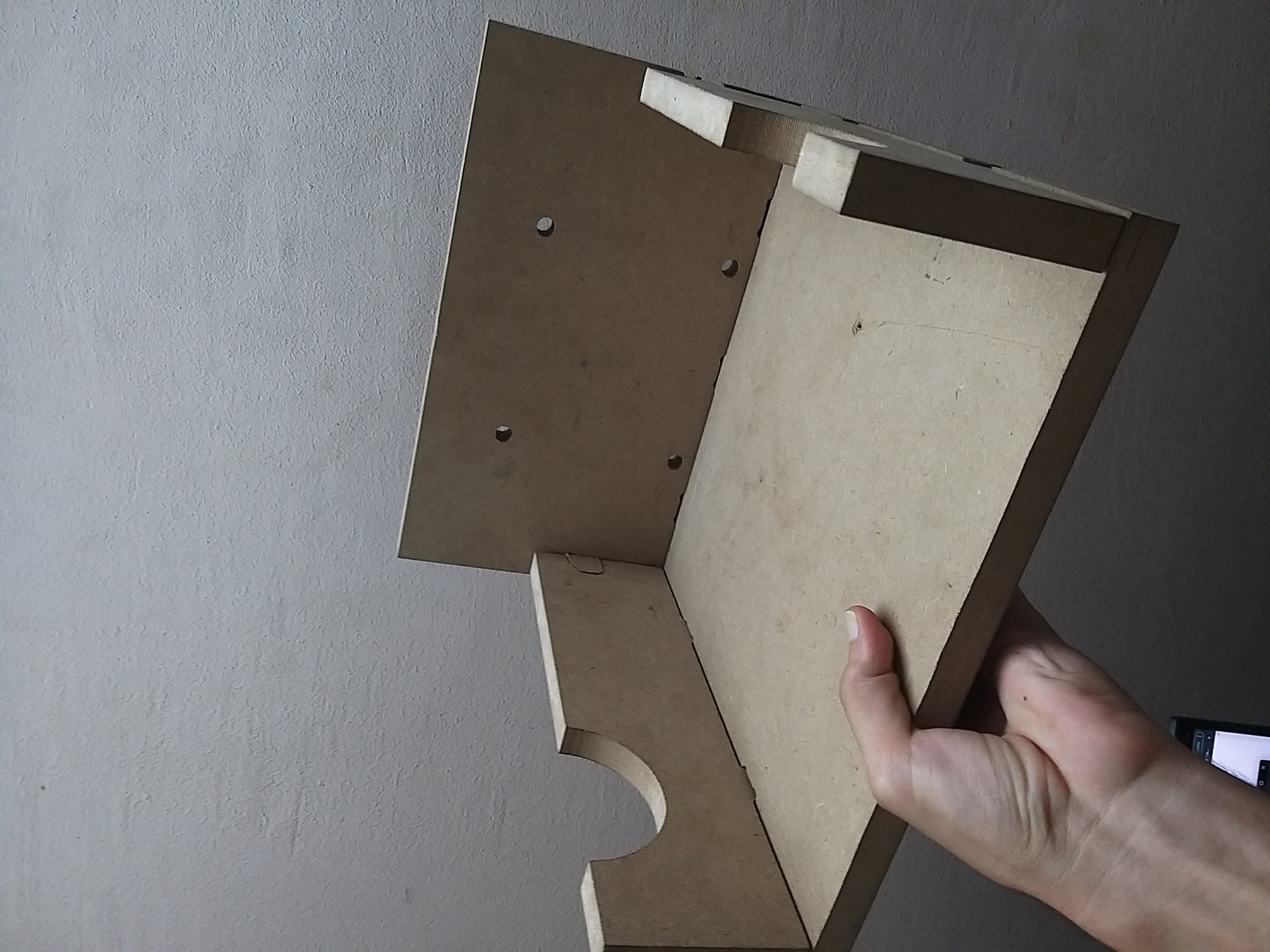

Step 6: Assembly

Assembly didn't go so well with me so I thought of adding extra support.

Finish!

Try it!

Unfortunately, I miss mesured the distance between holes in the wall so it isn't hanged yet.

Umm it needs some pads to protect the bike frame.

Notes to be considered:

1- Don't do any measuring before going to sleep

2- Invest in your first assembly as multiple assembly attempts only make it worse